VAT vacuum valves are designed for all vacuum levels up to high vacuum, ultra-high and extreme ultra-high vacuum conditions.

VAT vacuum valves are produced under clean room conditions and are tailor-made for their respective application. In addition to a high degree of purity, VAT vacuum valves are particularly convincing due to their highly precise function and durability, even under extreme process conditions.

With a comprehensive portfolio of vacuum isolation and control valves, gas dosing valves, transfer valves and venting and flood valves as well as fast closing valves, VAT offers the optimal solution for all application areas.

Technology decides

In order to permanently guarantee an optimal vacuum isolation or control function, VAT vacuum valves use different vacuum valve technologies developed by VAT. These patented technologies ensure, in addition to a particle-preventing function, precise operation over a high number of closing and control cycles.

VAT vacuum gate valves, vacuum angle valves for a wide range of applications as well as butterfly vacuum valves, pendulum vacuum valves or all-metal vacuum valves therefore set the standard for vacuum valve solutions in all areas.

Challenge us, we are looking forward to offer you an optimal solution as well.

In addition to the standard solutions presented on our website, we are also happy to develop solutions tailored to your vacuum system, just contact us.

For further information choose from the following valve categories:

FAQ Vacuum Valves

A vacuum valve is a device mounted in a supply or exhaust line of a vacuum system. It is usually used to isolate vacuum areas such as process chambers, or to control incoming and outgoing gas volumes. Vacuum valves can be operated manually, pneumatically, electropneumatically, electrically or electromagnetically. Vacuum valves are an integral part of any vacuum system and vacuum systems are used in a wide variety of industrial production applications.

Certain vacuum processes place particularly high demands on the purity as well as the chemical and physical stability of the process environment. This applies, for example, to almost all areas of semiconductor production as well as to many research facilities where vacuum systems are used. In the field of elementary research, the ability to deal with extreme conditions such as very high or low temperatures, strong radiation and extremely high vacuum (XHV) with pressures up to 10-15 mbar – the limits of what is currently technically feasible and measurable – are often added to these requirements.

Vacuum valves in these applications differ from standard vacuum valves in the following respects:

1) Minimized particle emission

High-performance vacuum valves are optimized not to release particles through their materials for housing, mechanics or seals by outgassing, nor through their opening and closing or control movements by friction. This is achieved by special selection and treatment of the materials used, and by certain design details that minimize or, in some cases, completely eliminate particle release.

2) Minimized motion pulses

Every valve generates motion pulses through its opening and closing movements. In the case of automatically driven valves, these can range from slight vibrations to audible and perceptible hard impacts. These motion pulses can have a negative impact on sensitive manufacturing processes, e.g. through additional particle release. In addition to design features, high-performance vacuum valves minimize these impulses primarily by controlling the motion in so-called motion profiles. Similar to the way that passenger elevators operate, the closing speed is slowed down shortly before the closing point is reached in order to prevent "hitting". These motion profiles can usually be modified so that, for example, they can be adapted to the desired conditions in terms of closing time and closing frequency.

3) Neutral chemical and physical behavior

Vacuum valves always change the homogeneity of a vacuum process chamber, in whatever form. This occurs, partly, as a result of their geometry. Narrowing or widening in the flow path can change the flow resistance and flow velocity, or dead spaces, such as travel spaces for valve plate, can promote deposition processes. This also occurs through the opening and closing motion, which alters flow behavior as well as the concentration, distribution, mixing and temperature of process gases. High-performance vacuum valves are optimized to compensate for such influences wherever possible or to make them controllable. To this end, a variety of additional techniques are incorporated into the designs that go far beyond the basic valve functions such as opening and closing or control.

4) Precisely reproducible behavior

High-performance vacuum valves differ from standard solutions primarily in their highly reproducible behavior. This means that while standard solutions exhibit fluctuations in each individual opening and closing movement and show deviations from their defined performance values over the period of use, high-performance vacuum valves are optimized to always exhibit the same behavior, defined within very narrow limits, over long intervals of use. This means that they stabilize vacuum processes and minimize process control complexity.

Vacuum valves, like other valves, use some basic mechanics such as gate valves, flap discs or rotary discs to separate or isolate vacuum areas and to control volume flows. However, the basic conditions for using these mechanics are completely different. For example, a high degree of freedom from particles, precise control of very small volume flows, hermetic sealing, minimal vibration and shock are crucial properties. As a result, these basic mechanics are usually designed differently for vacuum valves. For example, closing mechanisms are usually designed to close without friction and cause minimal vibration and shock, if any. Furthermore, control movements can be extremely finely dosed and seals are optimized so that ideally they do not release any particles and their static or dynamic properties remain stable over long periods of use.

The following basic types of vacuum valves are used:

1) Vacuum gate valves – Usually ideal for isolation or simpler control applications. Very narrow installation depth, maximum conductance (minimum flow resistance) but space required for the travel space of the gate. These can also take the form of vacuum slit valves, vacuum transfer valves or vacuum doors through which products are introduce into vacuum process chambers.

2) Vacuum angle valves – Universal general purpose vacuum valves. Very compact size, usually very modular in terms of seal, actuator and sensor. Average conductance, very easy maintenance. Very good and, if necessary, very precise controllability.

3) Vacuum butterfly valves – Primarily for control applications. Very narrow installation depth, good conductance, fast and precise controllability.

4) Vacuum pendulum valves – Very narrow installation depth and compact size, combined with very precise control behavior, very good insulation capacity and very high conductance.

5) Symmetrical flow vacuum control valves – Special type, optimized for a very homogeneous flow behavior from the first opening to the complete valve opening.

6) Gas dosing valves or leak valves – Especially for very fine dosing of, for example, process gases at low volume flows.

7) Pressure relief valves or venting valves – Safety valves that allow controlled – usually complete – ventilation of vacuum systems and prevent defined pressure conditions from being exceeded.

8) Vacuum check valves – Passive, volume flow and differential pressure operated valves. Usually used to protect vacuum systems from backflow contamination. Used, for example, between vacuum backing pumps and vacuum systems.

9) Fast closing valves – Active protection valves that usually protect larger vacuum volumes or chambers from vacuum loss due to leakage. Key feature: very fast closing response to detected pressure drop. In UHV and XHV applications, usually additionally supported by sector vacuum valves (usually vacuum gate valves) to ensure hermetic isolation even at very high differential pressures.

10) Vacuum all-metal valves – Special group of vacuum valves designed for extreme pressure, temperature and radiation conditions. Key feature: hard-on-hard (metal-on-metal) sealing rather than elastomeric seals which would not withstand service conditions.

11) Vacuum multi-valve units – Special type of vacuum valves that combine several vacuum valve functions in one unit. Key feature: reduced number of components, faster assembly. Usually tailor-made to customer requirements.

12) 3-Position vacuum valves – Special form of vacuum isolation valves in which a third valve position can be defined in addition to the closed and open positions. An application is for example to avoid pressure pulses due to the valve opening too quickly at high differential pressures. In the third position, the contact pressure on the seal is slightly reduced for a short time without the valve being visually open, resulting in a smoother pressure change.

In addition to these basic types, there are also a large number of hybrid variants, some of which combine different valve technologies or offer solutions for certain special requirements.

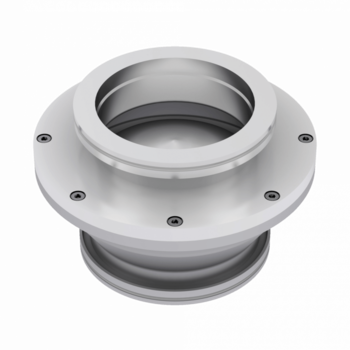

A vacuum valve typically consists of several key components, each serving a specific function to control and maintain the vacuum within a vacuum system. The main body, usually made from aluminum or stainless steel, houses the internal parts. It include a seals to prevent leaks and a tight closure. Common types include elastomer or metal seals. The actuator, which can be manual, pneumatic or electric, is responsible for opening and closing the valve. The gate, depending on the valve type, moves to block or permit gas flow. Additionally, the valve features ports, including an inlet and outlet opening, which facilitates gas flow. Together, these components enable precise control over the vacuum conditions. Different types of vacuum valves, such as gate valves, angle valves, butterfly valves, transfer valves, … may have variations in these components to suit specific applications.