Electron Microscopy, Metrology, Inspection & Defect Review

The control of the vacuum environment used in the field of electron microscopy, metrology, inspection & defect review requires high-precision vacuum v...

Read moreThe main requirement of a modern venting valve is a reliable, precise and fast-acting venting mechanism. A degree of modularity allowing configurations that can address various process and installation conditions is also important.

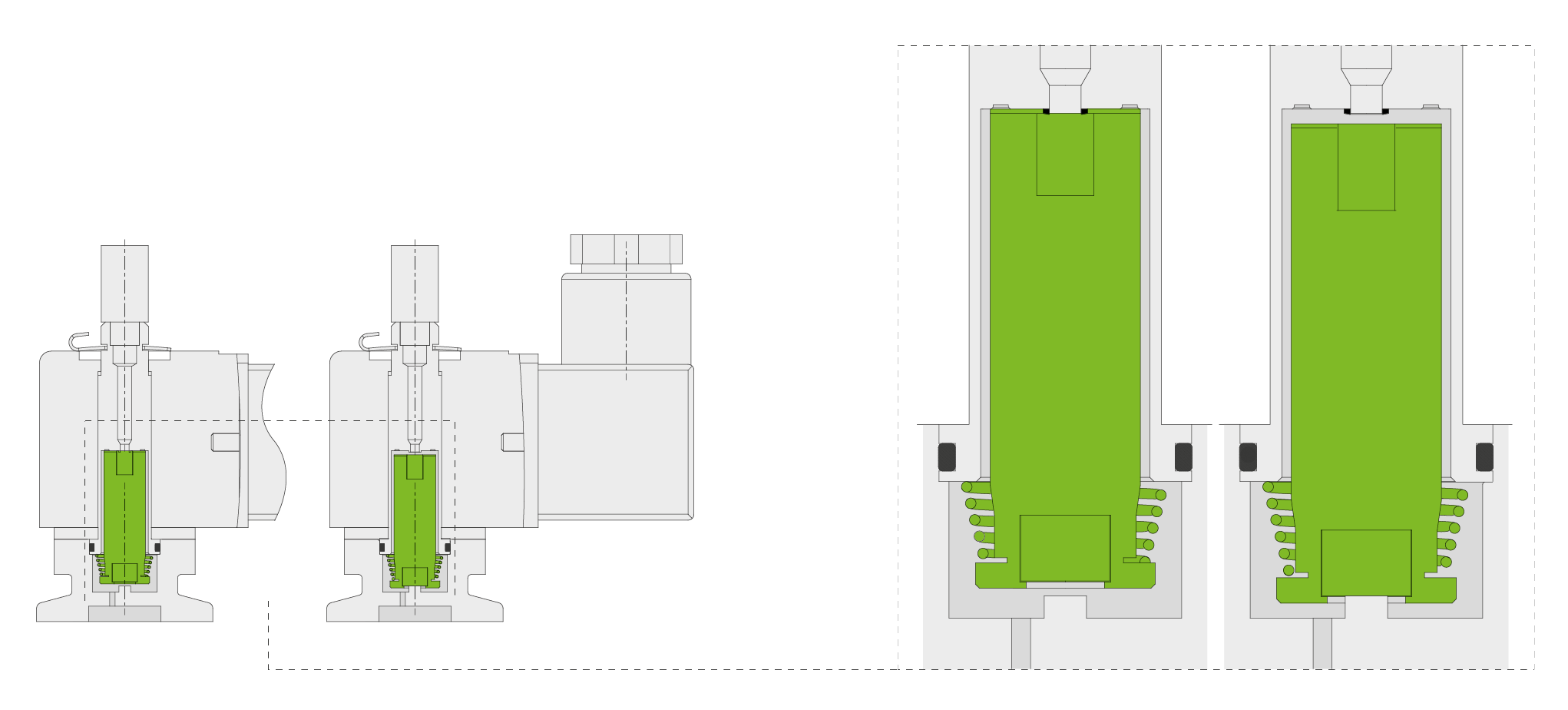

The 21.3 venting valve is laid-out to address nearly all venting requirements of vacuum systems. Designed for a reliable, extended service-free operation, the series is available with manual as well as automatic actuation.

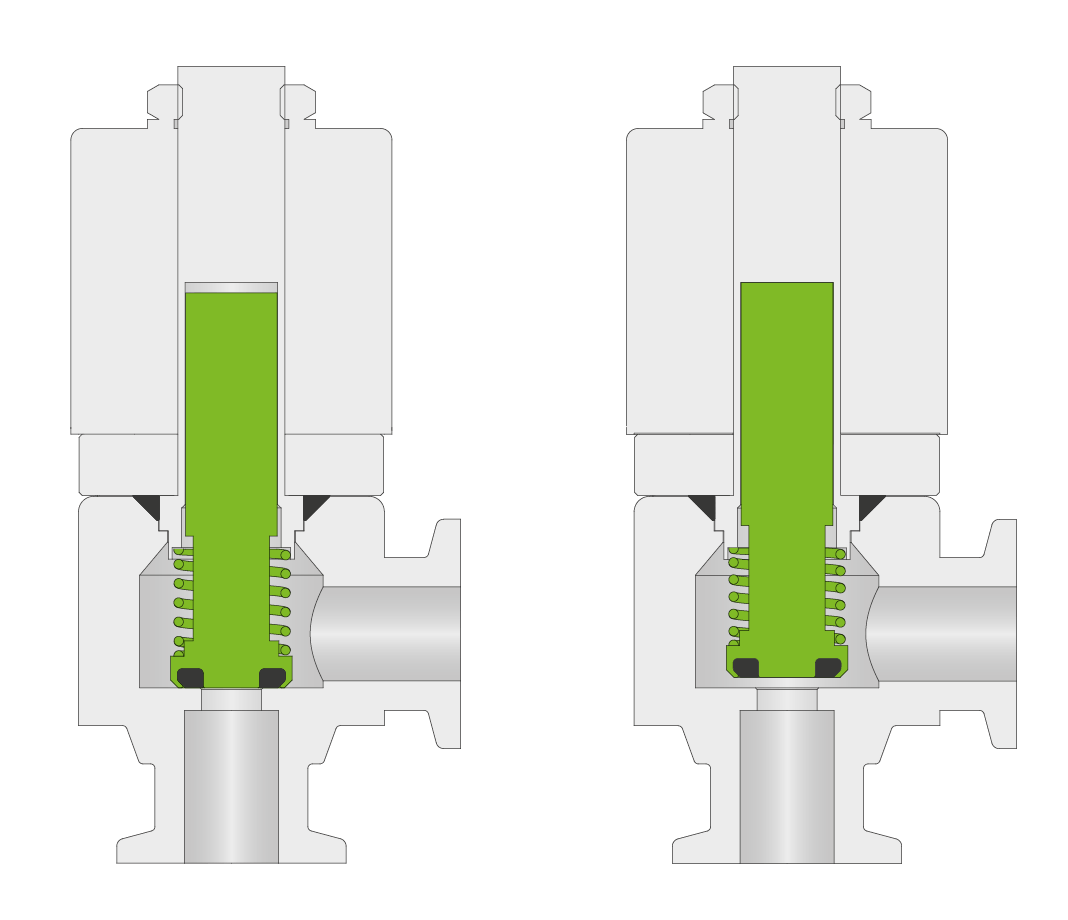

The electromagnetic actuated automatic version stands out in particular for its special design. The elimination of any feedthrough and fully enclosed operation with the actor as closing device allows outstandingly fast operation without the service requirements of normal valves with shaft feedthrough. It also eliminates leakage risks.

The automatic version also offers a failsafe mechanism that reacts in case of power loss. The mechanism is available in failsafe closing or opening configurations (NC or NO version) to address both process and installation requirements.

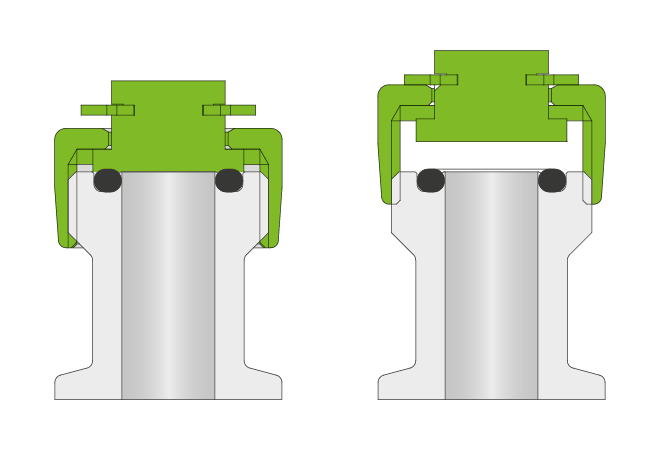

Manual

Electromagnetic:

single acting with closing spring (NC)

Electromagnetic:

single acting with opening spring (NO)

The operating pressure range of the 21.3 is between 1ₓ 10-8 mbar and 1.2 bar (abs) with a gas flow of 50 l in 14 sec. (manual), 100 l in 30 sec. (NC version) and 50 l in 270 sec. (NO version).

Tested in thousands of demanding applications under various process conditions, the 21.3 has proven its outstanding reliability.

Features:

Benefits:

| Manual | Electromagnetic with Closing Spring (NC) | Electromagnetic with Opening Spring (NO) | ||

|---|---|---|---|---|

| Sizes | DN 10 mm (⅜") | DN 10 mm (⅜") | DN 10 mm (⅜") | |

| Actuators | Manual | Electromagnetic with Closing Spring (NC) | Electromagnetic with Opening Spring (NO) | |

| Body Material | Aluminum and Stainless Steel | Aluminum | Aluminum | |

| Standard Flanges | ISO-KF | ISO-KF | ISO-KF | |

| Leak Rate | Valve Body, Valve Seat | < 1 × 10-9 mbar ls-1 | < 1 × 10-9 mbar ls-1 | < 1 × 10-7 mbar ls-1 |

| Pressure Range | 1 × 10-8 mbar to 1 bar (abs) | 1 × 10-8 mbar to 1 bar (abs) | 1 × 10-8 mbar to 10 bar (abs) | |

| Differential Pressure on the Plate | In Closing Direction In Opening Direction | – – | 10 mbar 1 mbar | – – |

| Differential Pressure at Opening | In Closing Direction In Opening Direction | – – | 2 mbar 1 mbar | – – |

| Cycles until first Service | – | 1.5 Million | 3 Million | |

| Temperatur | With Aluminium Body With Stainless Steel Body | 0– 80 °C 0– 120 °C | 5 –40 °C – | 5 – 50 °C – |

| Material | Aluminium Valve Body | EN AW-6023 (3.0306) | EN AW-6082 (3.2315) | EN AW-6026 |

| Stainless Steel Valve Body | AISI 303 (1.4305) | – | – | |

| Plate: Aluminium Valve Stainless Steel Valve | EN AW-6023 (3.0306) AISI 304 (1.4301) | – | – | |

| Seal | FKM (Viton®) | FKM (Viton®) | FKM (Viton®) | |

| Feedthrough | None | None | None | |

| Mounting Position | Any | Any | Any | |

| Power Supply | – | 200– 240 VAC, 50/60 Hz 100– 115 VAC, 50/60 Hz 24 VAC, 50/60 Hz 24 VDC | 200– 240 VAC, 50/60 Hz 100– 115 VAC, 50/60 Hz 24 VDC | |

| Venting Time | 50 l in 14 sec. | 100 l in 30 sec. | 50 l in 270 sec. | |

| Weight | Aluminium Valve Stainless Steel Valve | 0.1 kg/0.22 lbs 0.15 kg/0.33 lbs | 0.46 kg/1.01 lbs – | 0.1 kg/0.22 lbs – |