Proton Therapy

Proton therapy as a medical treatment process is implemented in different technical concepts, with different requirements for the vacuum systems invol...

Read moreThe main requirement of a beam stopper is a reliable acting stop mechanism.

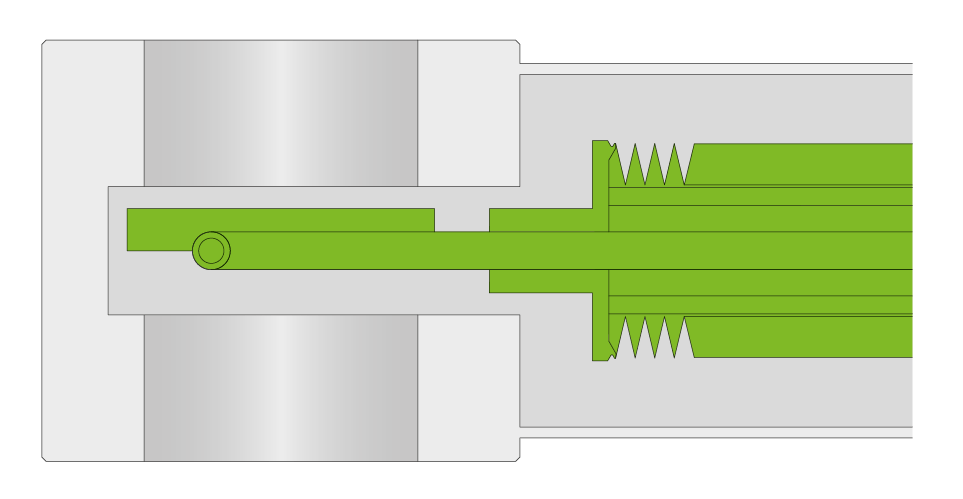

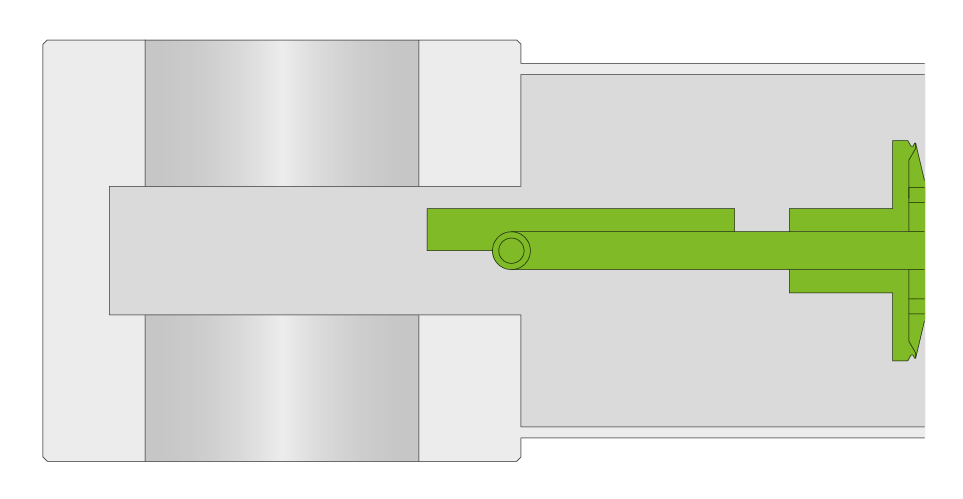

The 79.3 Beam Stopper Insert version provide reliable protection from energy radiation in UHV and XHV applications. The beam power load of the stop mechanism with a water-cooled copper plate is up to 6 kW at beam diameters > 60mm and up to 5 kW at diameters < 60mm. The specific load is max. 25W/mm².

To address UHV and EHV requirements the 79.3 has a one-piece water-cooling guide with no welding or soldering seam between the water supply and the vacuum. A non-cooled version is available as well.

The 79.3 is pneumatic actuated. The standard bake out temperature is max. 250°C for the beam stopper body and max. 80°C for the actuator (optional max. 200°C). The bonnet is metal sealed and the feedthrough sealed by a welded metal bellows.

Already proven in all leading energy beam facilities under various process conditions, the 79.3 Beam Stopper Insert series have become the standard for beam stopping.

79.3 Beam Stopper Insert series is available in DN 63 - 160mm (2½” - 6”). The body material is stainless steel. The standard flange connector is CF-F. Customer specific flanges are an option, also additional ports for roughing (by-pass), venting or for gauges.

Standard time until first service is 5.000 cycles. If required an extended version of 50.000 cycles is available.

| Sizes | DN 100 (4"), DN 160 (6"), DN 200 (8") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting | |

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | CF-F | ||

| Leak Rate | Beam stopper body | < 1 × 10-10 mbar ls-1 | |

| Pressure Range | UHV to 1 bar (abs) | ||

| Cycles until first Service | 5000 (Option: 50 000) | ||

| Bake-Out Temperature | Beam stopper body | ≤ 250°C | |

| Actuator | ≤ 80°C (Option: 200°C) | ||

| Heating and Cooling Rate | ≤ 80 °C h-1 | ||

| Material | Beam stopper body | AISI 304 (1.4301) | |

| Mechanism | AISI 304 (1.4301) | ||

| Bellows | AISI 316L (1.4404) | ||

| Watercooled plate | Copper | ||

| Seal | Bonnet | Metal | |

| Mounting Position | Any | ||

| Compressed air (Min.-Max. Overpressure) | 4– 7 bar / 58 – 102 psi | ||

| Closing time | DN 100 DN 160 | 2 s 3 s | |

| Load | Beam Ø <60 mm Beam Ø > 60 mm | max. 5 kW max. 6 kW | |

| Specific load | max. 25 W / mm2 | ||

| Cooling water | Quanitity Temperature | min. 15 l / min < 15 °C | |