Solar Thin Film Deposition

Solar panel manufacturers use a variety of coating processes (CVD, ALD, MBE, PVD, etc.) to produce the ultra-thin films that make up the performance o...

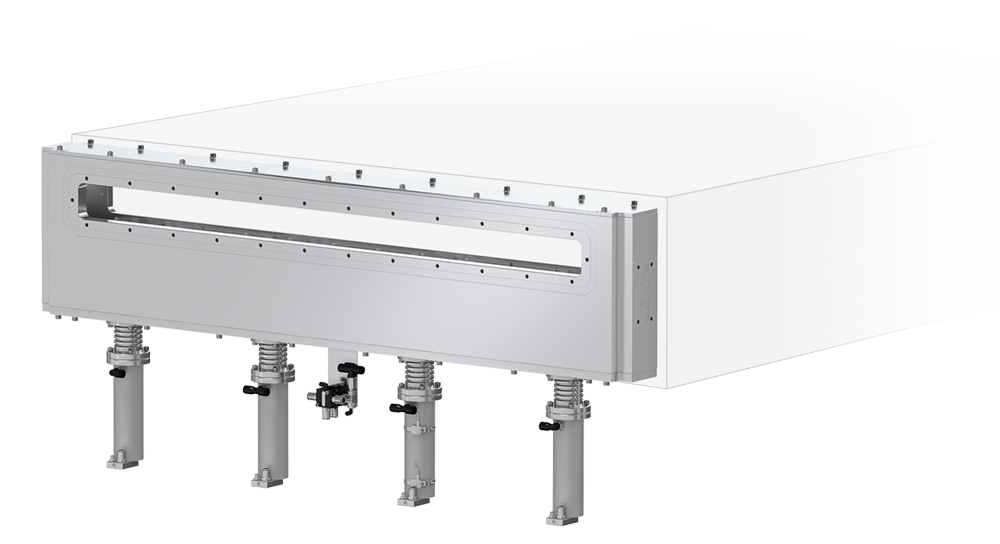

Read moreThe 06.6 Large Transfer Valve / Insert / Door sets new standards for PV and large coating systems. It has been developed to address three different installation and usage requirements (transfer valve, insert and atmospheric door) in one solution with a focus on high system throughput supported by short opening and closing times, even when used for high temperature processes.

The 06.6 series is defined by three key performance measures, high reliability, high uptime and low maintenance, and stable, high cycle performance.

The core design of the 06.6 is designed for high and long uninterrupted production cycles - up to one million cycles - under standard temperature conditions. Optional design features like a thermal deformation compensation or a defined O-ring compression increases the performance of the 06.6 series.

Down time for maintenance or repair is not just an annoyance, it is a cost and it reduces output. The 06.6 maximizes uptime by design. This is characterized by two key features: a robust design that performs reliably under varying process conditions and an extended maintenance cycle with only basic maintenance requirements. Both increase the effective uptime.

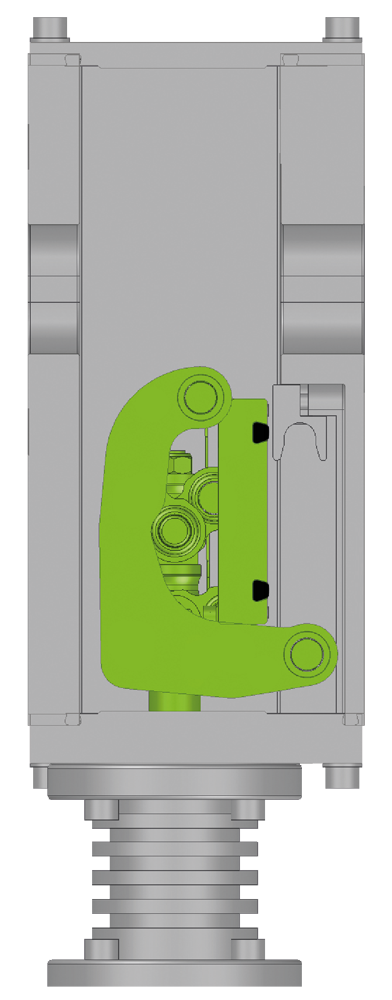

If maintenance is required, it easily can be aligned with the maintenance schedule of the production system. A maintenance exchange of all moving parts, if required, can be performed very quickly which means it would not result in system maintenance down time.

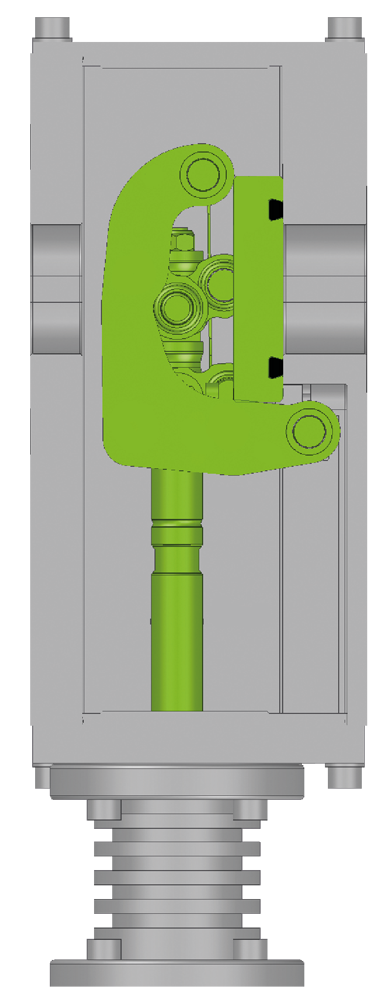

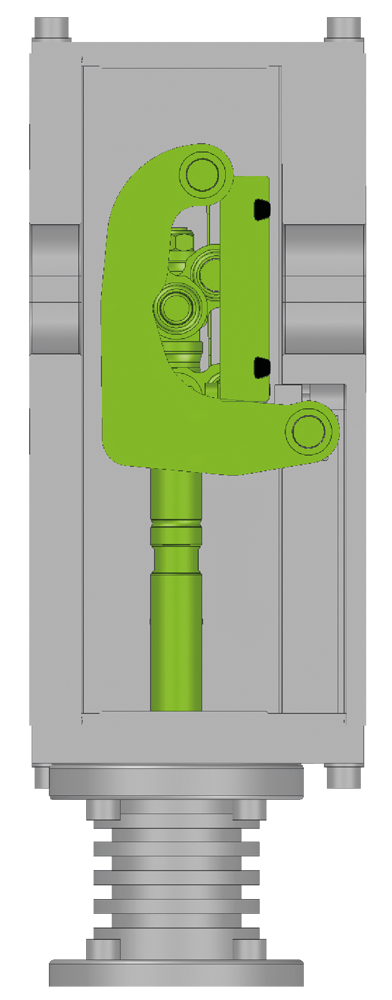

In addition, the optional “Defined O-ring Compression” feature reduces seal wear and as such, it delivers an extended O-ring life. It also provides a more stable sealing performance throughout the O-ring lifetime. Peek tabs on the plate avoid direct contact between valve housing and valve plate to achieve the defined compression.

The exceptional fast opening and closing cycle performance (≤ 2 s) with 100 mm opening height of the 06.6 series is achieved by VAT’s special SolVAT technology. In a single linear motion, the gate is moved above the opening and then pressed to seal the opening in under 2 seconds.

With various design options, the 06.6 series can be customized to a wide range of requirements. Solenoid valve for impulse actuation, water cooling and a variety of material options are just some of the customizing options.

To learn more about the 06.6 series get in touch or send us an inquiry.

Features:

Benefits:

| Body Material | Aluminum or Stainless Steel | ||

|---|---|---|---|

| Feedthrough | Shaft Feedthrough | ||

| Leak Rate | Valve Body | < 1 × 10-7 mbar ls-1 | |

| Valve Seat | < 1 × 10-5 mbar ls-1 | ||

| Differential Pressure | On the Gate | ≤ 1 bar | |

| At Opening | ≤ 5 mbar | ||

| Cycles until first Service | 1 Million | ||

| Closing or opening time | ≤ 2 s (with 100 mm opening height) | ||

| Temperature | Aluminium Valve Body/Flanges | ≤ 120 °C | |

| Stainless Steel Valve Body/Flanges | ≤ 200 °C | ||

| Actuator, Position Indicator | ≤ 80 °C | ||

| Material | Aluminium | EN AW-6082 (3.2315), EN AW-5083 (3.3547) | |

| Stainless Steel | AISI 304 (1.4301), AISI 316L (1.4404) | ||

| Actuator Shafts | AISI 304 (1.4301) hard-chrome plated | ||

| Seal | Gate, Flanges, Feedthrough | FKM (Viton®) | |

| Mounting Position | Actuator up, down or lateral | ||

| Position Indicator | Voltage | 10– 30 VDC PNP (NPN optional) | |