Process Control & Isolation

High-precision control and isolation of vacuum and gas flows is essential in semiconductor manufacturing. In both upstream and downstream processes, a...

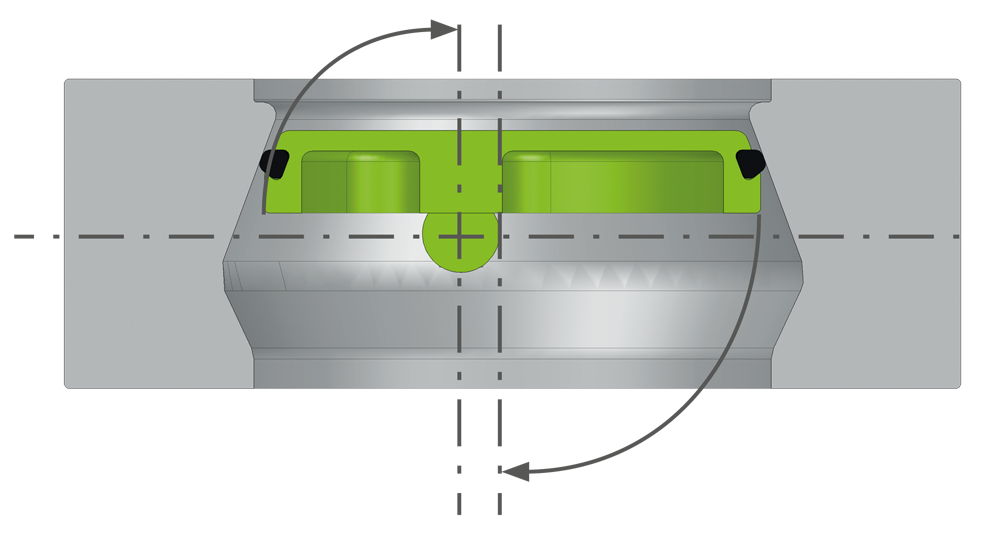

Read moreThe 61.6 HV Control Butterfly Valve delivers outstandingpressure control and isolation performance. With its fastand precise acting motion controller (0.45 s) it’s the perfectsolution for fine control and isolation in CVD processes.The plate acts as a throttling element and varies theconductance of the valve opening. The integrated pressurecontroller of the 61.6 calculates the required plate positionto achieve the set pressure as fast as possible.

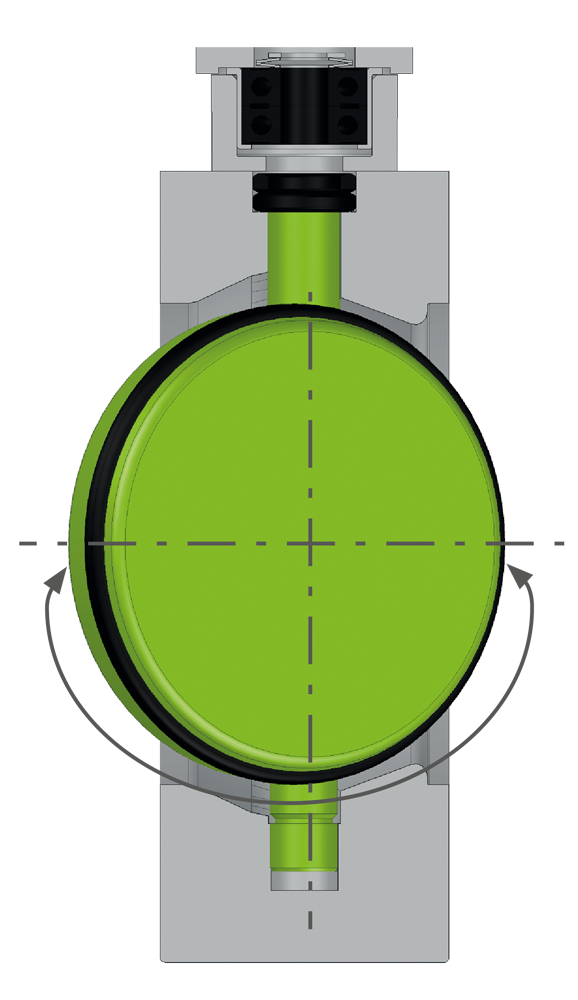

The 61.6 series isolation function is specially designedto avoid the characteristic higher seal wear of butterflyvalves. With it out-of-center plate shaft and the specialgeometry of the valve body and seal seat, seal friction isminimized and the sealing performance is increased.

Already installed in thousands of demanding applicationsunder various process conditions, the 61.6 series hasproven its outstanding reliability. With a robust designand direct mounting option, as well as reduced and easymaintenance, the 61.6 series convinces in all aspects.

Various design options in body material, surface treatment,elastomers, flange connections, sealing material, specialsizes as well as special control algorithms (adaptive, fix PIdown-stream/soft-pump) simplify the integration of the61.6 series into various vacuum applications.

61.6 HV Control Butterfly Valves are available inhard anodized aluminium or stainless steel withstandard flange connectors in ISO-KF and ISO-F.Customer-specific flanges can be integrated, aswell as special features like integrated heater withinsulation. FFKM/FKM elastomers are available onrequest (FKM is standard).

Features:

Benefits:

| Sizes | DN 40 (1 ½"), DN 50 (2"), DN 63 (2 ½"), | |

|---|---|---|

| Actuator | Integrated Controller with Stepper Motor, field oriented control (foc) | |

| Body Material | Hard anodized Aluminum or Stainless Steel | |

| Standard Flanges | ISO-KF, ISO-F | |

| Leak Rate: Valve Body | Hard anodized Aluminum Stainless Steel | < 1 × 10-5 mbar ls-1 < 1 × 10-9 mbar ls-1 |

| Leak Rate: Valve Seat | Hard anodized Aluminum Stainless Steel | < 1 × 10-4 mbar ls-1 < 1 × 10-9 mbar ls-1 |

| Pressure Range | Hard anodized Aluminum Stainless Steel | < 1 × 10-6 mbar to 1.2 bar (abs) < 1 × 10-8 mbar to 1.2 bar (abs) |

| Cycles until First Service1) | Pressure Control Isolation | 2 million 250 000 (DN 40 - 50) 100 000 (DN 63 - 100) |

| Temperature | Valve Body Controller | ≤ 120 °C Max. 50°C (≤ 35 °C recommended) |

| Material | Alu Valve Body/Plate SS Valve Body/Shaft | EN AW-6082 (3.2315) AISI 316L (1.4404 or 1.4435) |

| Seal | Plate Feedthrough | FKM FKM |

| Feedthrough | Rotary Feedthrough | |

| Mounting Position | Valve Seat towards Chamber |

1) Maximum values depending on operating conditions and sealing materials