High Energy Physics

In high-energy physics research, experiments and measurements in many experimental setups take place partly or entirely under vacuum conditions. This ...

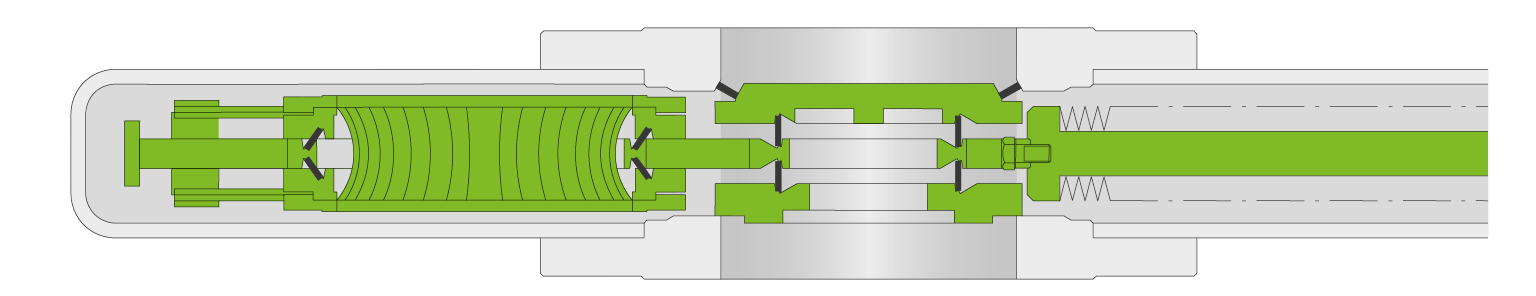

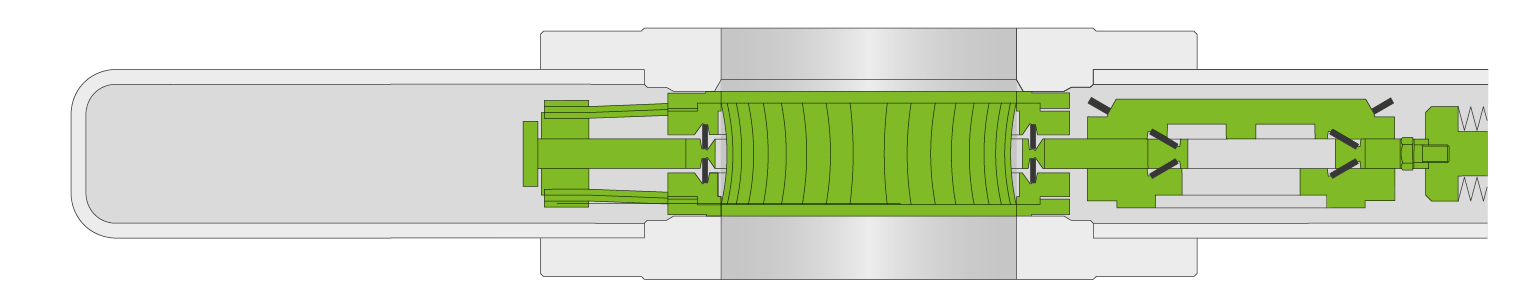

Read moreThe 47.2 XHV RF All-Metal Gate Valve series is designed to bridge the space between the flanges in open valve position with an RF contact that matches the dimensions of the beam tube. In addition to the RF contact there is also electrical contact between the flanges. This guides the particle beam and the RF field with minimal losses through the valve.

In closed valve position these state-of-the-art all-metal valves deliver reliable isolation. This includes high radiation resistance (up to 108 Gy), high bake out temperature as well as a durable and reliable "hard on hard" sealing system.

The 47.2 XHV RF All-Metal Gate Valve series is equipped with VATRING sealing technology. This dynamic all-metal sealing system is capable of consistently reliable sealing and constant closing forces. It enables high sealing forces with comparable low axial forces. The sealing partners are made from stainless steel and they deform elastically only. The valve bake out temperatures can be up to 300°C, in open and closed position.

The all-metal valves are designed and tested for a lifetime of 10 000 cycles (DN 40mm - 160mm) and 5 000 cycles (DN 200mm). However, the sealing system is good for 100 000 leak-tight closures in a clean vacuum environment.

Already installed in nearly all accelerator and synchrotron facilities worldwide, the 47.2 series have proven their outstanding reliability. They set the standard for RF-valve applications.

The valves are available from DN 40mm to DN 200mm (1 ½ ” - 8”). The standard flange is CF-F. The valve RF aperture is adapted to the customer beam profile. Nearly all beam tube shapes can be realized.

The distance between the gate body and the actuator can be extended to maximize the bake out temperature. Additional options include an anti-magnetic version with defined permeability, RF contact with low permeability material, different wave-guide executions, different solenoid and position indicator configurations as well as ports for roughing, venting or for gauges.

Features:

Benefits:

| Sizes | DN 40 (1½"), DN 63 (2½"), DN 100 (4"), DN 160 (6"), DN 200 (8") | ||

|---|---|---|---|

| Actuator | Pneumatic | Double acting | |

| Body Material | Stainless Steel | ||

| Feedthrough | Bellows | ||

| Standard Flanges | CF-F | ||

| Sealing technology | VATRING “hard on hard“ sealing | ||

| Leak Rate | Valve Body | < 1 × 10-10 mbar ls-1 | |

| Valve Seat | < 1 × 10-10 mbar ls-1 | ||

| Pressure Range | XHV to 2 bar (abs) | ||

| Differential Pressure | On the Gate | ≤ 1 bar | |

| At Opening | ≤ 500 mbar | ||

| Cycles until first Service | DN 40 – 160 DN 200 | 10 000 5 000 | |

| Temperature | Valve Body | ≤ 300 | |

| Pneumatic Actuator | ≤ 200 °C | ||

| Solenoid Valve | ≤ 80 °C | ||

| Position Indicator | ≤ 80 °C (Option: 200 °C) | ||

| Heating and Cooling Rate | DN 40 – 160 DN 200 | ≤ 50°C h-1 ≤ 25°C h-1 | |

| Material | Valve Body | AISI 316L (1.4404, 1.4435) | |

| Mechanism | AISI 316L (1.4404, 1.4435) | ||

| Bellows | AISI 316L (1.4435) | ||

| RF Contact | AISI 301 (1.4310), thermoresistant silver-coated | ||

| Seal | Bonnet | Metal | |

| Gate | Metal | ||

| Mounting Position | Beam Line horizontal, otherwise any | ||

| Solenoid Valve | 24 VDC, 2.5 W (others on request) | ||

| Position Indicator: Contact Rating | Voltage | ≤ 50 VAC/DC | |

| Current | 80°C: ≤ 1.2 A | 200°C: ≤ 1 A | |

| Valve Position Indication | Visual (Mechanical) | ||