Sub-Fab Systems

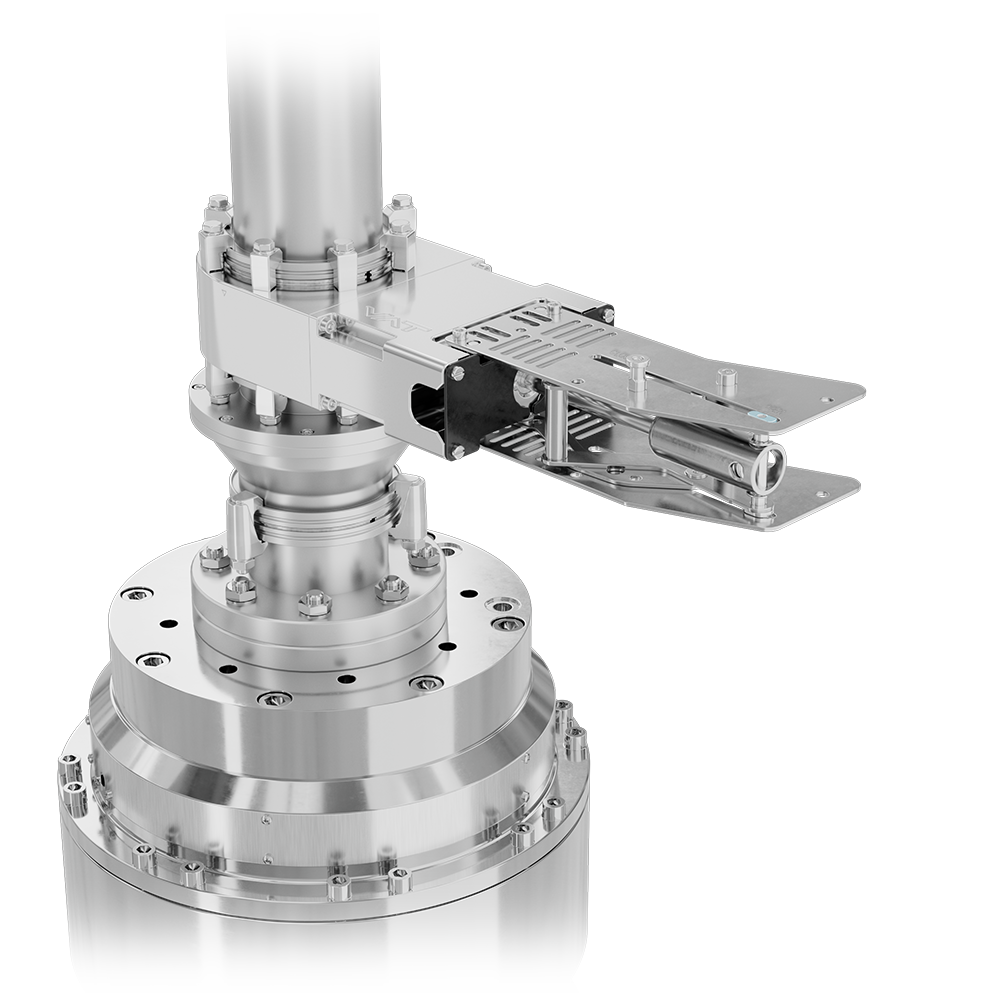

Sub-fab processes can be challenging: corrosive, abrasive, and toxic gases and/or condensation and high levels of by-products in the gas stream can al...

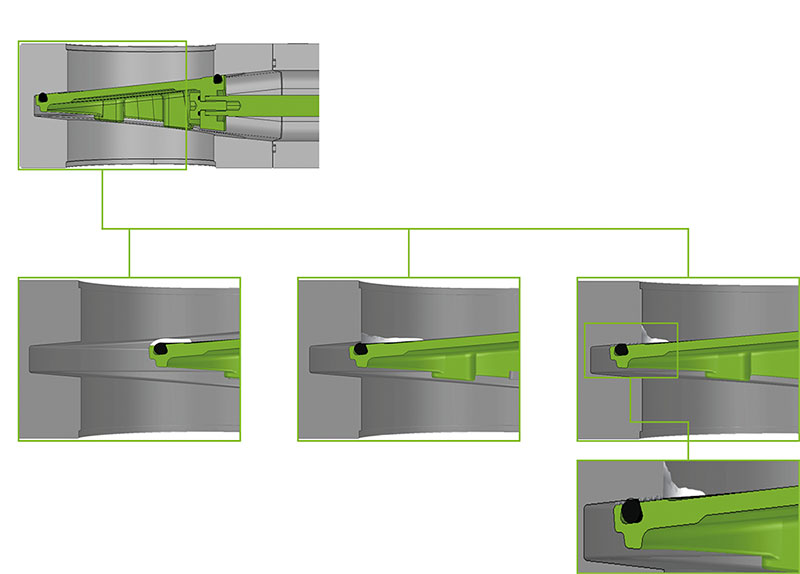

Read moreHigh proportions of by-products in the gas flow can lead to valve malfunctions as well as unplanned maintenance work due to the formation of deposits. The 09.2 HV Gate Valve with Wedge Design prevents this. Thanks to its special wedge design with self-cleaning function, it closes and opens reliably even if there are heavy deposits on the valve seat. Due to the wedge-shaped design of the gate, possible deposits are pushed off the valve seat or the gate seal to always guarantee a reliable sealing.

The 09.2 HV gate valve with wedge design is a manual valve with a patented easy to close and save lock technology.

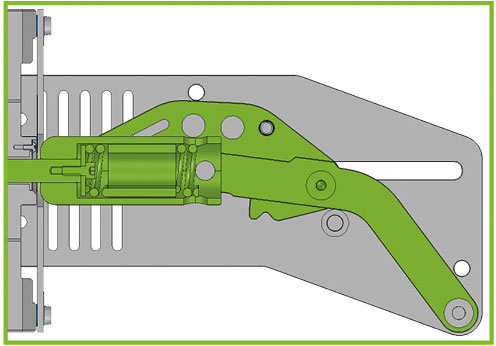

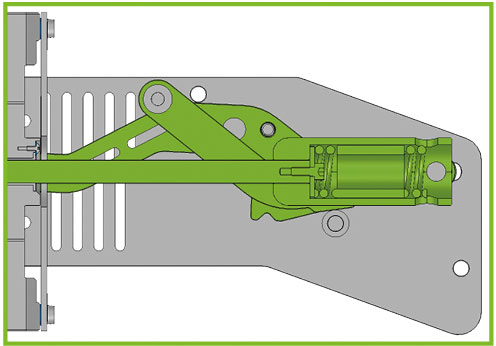

The one-swing lever mechanism allows a fast closing of the gate with just one movement. It guaranties reliable isolation of the gas stream as it locks the plate in the closing position and is fully functional at up to 1 bar differential pressure.

Already installed in thousands of demanding applications under various process conditions, the 09 series with wedge design has proven its outstanding reliability. Especially in sub-fab applications, it has become the standard solution for vacuum pump isolation.

The 09.2 is available in aluminum with ISO-F flange connection in sizes DN 100 and DN 160. The 09.2 has a visual position indicator. The seal material is FKM. An optional heating jacket can be fitted to the 09.2 to allow an operation at higher temperature. The 09.2 is designed for a maximum operation temperature of 150 °C at the valve body.

Wedge shape design of the gate and the valve seat creates the self-cleaning mechanism, avoiding any risk of leakage by maintaining the full sealing function of the O-ring.

Features:

Benefits:

| Sizes | DN 100 (4“), DN 160 (6“) | ||

|---|---|---|---|

| Actuator | Manual | ||

| Body Material | Aluminium | ||

| Feedthrough | Shaft Feedthrough | ||

| Standard Flanges | ISO-F | ||

| Leak Rate | Valve Body | < 1 × 10-9 mbar ls-1 | |

| Valve Seat | < 1 × 10-5 mbar ls-1 | ||

| Pressure Range | 1 × 10-8 mbar to 1.2 bar (abs) | ||

| Differential Pressure | At Gate | ≤ 1.2 bar | |

| Differential Pressure at Actuation | In opening direction | ≤ 1 bar | |

| In closing direction | ≤ 30 mbar | ||

| Conductance (Molecular Flow) | 1700 ls-1 | ||

| Cycles until first Service | 500 (unheated and under clean conditions) | ||

| Temperature | Valve Body | ≤ 150 °C | |

| Actuator | ≤ 100 °C | ||

| Heating and Cooling Rate | 50 °C h-1 | ||

| Material | Valve Body | EN AW-6061 T651 | |

| Gate | AISI 304 (1.4301, 1.4308) | ||

| Actuator | AISI 304 (1.4301) | ||

| Seal | Bonnet, Gate | FKM | |

| Mounting Position | Horizontal | ||

| Weight | 7.5 kg / 16.5 lbs, 15.5 kg / 34.5 lbs | ||